Air Duct Silencers: Commercial – Industrial – HVAC

Silencers or Air Duct Silencers are an engineered product specifically designed to control airborne noise in ducts, openings in buildings, enclosures, or from equipment. They may also be referred to as industrial sound attenuators.

Silencers are the best and most efficient solution to airflow generated noise. In the noise control world, acoustical silencers can provide huge sound reduction. Any fan or blower that is expelling air directly into the atmosphere will need a silencer. Cooling fans for Genset Radiators, because of the high volume of air needed will require silencers for intake and exhaust air.

Their noise reduction capabilities make them ideal for commercial use at hospitals, conference rooms, hotels and office buildings in which a silent environment is preferred. Our industrial silencers are custom engineered to meet the requirements of any application. Spatial limitations, fan requirements and pneumatic pressure drops are all factors that call for particular attention when incorporating noise control products, including sound traps and duct silencers, into the existing system construction.

Examples of Duct Silencers and Their Applications:

- Acoustical Silencers – Reduction of sound reverberation

- Gen-Set Silencers – Control noise produced by generators/engines

- HVAC Silencers – Duct sound attenuators for building ventilation systems

- Sound Traps – Reduce sound volume from noisy machinery on the factory floor

We provide expert engineering support, such as sound surveys, noise analysis, feasibility studies and acoustic consulting, to ensure that the product you receive is the best fit for your needs.

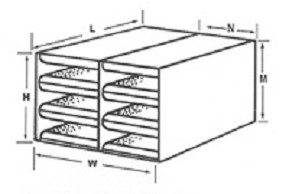

Standard and Custom Duct Silencers

- For projects that necessitate silencers that are larger than the maximum standard dimensions (48″ x 48″), we carry rectangular duct silencers. These can be fabricated as two separate standard silencers and constructed to fit the structure you are working with.

- We also carry round duct silencers with features including but not limited to: galvanized perforated sheet metal, spun head to reduce pressure loss, a pressure light casing.

Industrial Duct Silencers

Openings into or out of noisy environments are primary systems for the application of industrial duct silencers. These consist of utility rooms, building ventilation systems, etc. Imagine how difficult it would be to work in a conference room filled with the noise of a fan motor, or recovering from an illness in a hospital room only to be disturbed

by the sounds from a loud duct right outside the window. Noise control measures, such as silencers, allow the air to flow freely from the necessary generators without the addition of any unwanted sound.

eNoise Control offers a complete range of standard and custom engineered industrial duct silencers to satisfy your noise control needs. Effective noise control works to reduce noise through engineering. We provide you with the design and engineering assistance to integrate our silencer designs into a total system solution. We optimize our engineered silencers to ensure comfort, health and safety. At the same time, our engineering services assist you in complying with environmental regulations and community standards.

eNoise Control’s standard and custom engineered duct sound attenuators, vast sound reduction knowledge, and professional staff makes us the best place to go for your noise control project.

Industrial Silencer Options:

- Galvanized, carbon or stainless steel casing

- Duct Extension

- All welded construction

- Weather Hood

- Birdscreen

- Painted Exterior

- Access Doors/Panels

- Filters

Circular Silencers:

- Cylindrical pressure-tight casing

- Streamlined acoustic core baffle

- Acoustic media protected by galvanized perforated sheet metal

- Spun head for reduced entrance pressure loss

- Tapered tail optimally designed for velocity pressure regain and insertion

Silencer Sound Reduction

Silencer’s sound reduction is expressed in insertion loss is reported in units of dB. It is a measure of the true attenuation or noise reduction of a silencer. Insertion loss can be directly subtracted from the noise levels of a fan or other noise maker that the silencer is attached to achieve the resultant, quieted noise levels. Generated noise is what happens due to air flowing through the silencer and is of concern in the supply air mode only. That is, supply air enters the silencers at one face velocity (fpm) and then speeds up as it moves past or between the silencer baffles or silencing bullet. Downstream (exit) of the silencer, the air expands to fill the space. The space can be the inside of ductwork, a stack or worst case the atmosphere (termed an abrupt expansion).

This expansion causes silencer generated noise. It is like blowing through a whistle or straw. The air speeds up then expands. This expansion causes sound (generated noise). Therefore, you ‘don’t get something for nothing’. With a silencer under positive/forward/supply airflow you get attenuation (insertion loss) and generated noise. One final issue, generated noise and insertion loss are both a function of pressure drop. The higher the silencer pressure drop, the greater the generated noise levels and insertion loss values. As long as you have a pressure loss equal to or less than 0.35 inch WG, generated noise is not a problem.

If you are in need of duct silencer for your sound control needs, please give us a call at 888.417.1903 or send an email to info@enoisecontrol.com.