Liquid Chiller Compressor Sound Control – Case Study

Situation:

A county correctional complex had been enduring high noise levels in their first floor office area for approximately 10 years when they contacted eNoise Control. The noise was emanating from a basement mechanical room located directly below the offices. After continuous complaints from administrative staff and officers, management decided to address the noise problem.

eNoise Control recorded 1/3 octave band sound level readings in the basement mechanical room (98 – 100 dBA) and the first floor offices (70 – 75 dBA). It was determined that the primary noise generator was a large Liquid Cooled Chiller which exceeded 100 dBA above the unit. The noise levels in the basement mechanical room exceeded OSHA limits for worker safety and engineering controls were recommended for the Chiller Unit.

Solution:

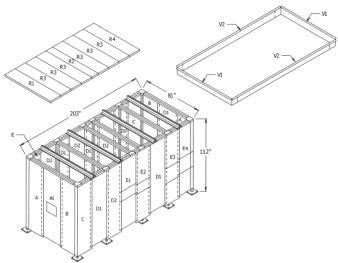

eNoise Control designed and installed a sound curtain enclosure. The four sided enclosure with roof was constructed of tubular steel uprights and base plates supporting a rigid panel roof and a double track hook and trolley panel suspension system. The sound curtain panels were a 1lb. per square foot loaded vinyl sound barrier bonded to a 2” thick acoustical absorber with a vinyl facing. The panels are suspended from a double track with hook and trolleys where alternating panels ride on a separate track so the panels will slide behind each other providing accessibility for maintenance. Four silenced ventilation panels coupled with roof mounted fans provided cooling air for the equipment. Four 1 lb. per square foot clear vinyl windows were strategically positioned within the curtain panels to allow viewing of the gages without opening the enclosure.

The customer’s noise reduction goals were exceeded in the basement mechanical room (18-20 dBA reduction) and the first floor offices (20 – 24 dBA reduction). The staff was pleased with the quieter work environment and management enjoyed a happier safer workplace.

Please call eNoise Control to discuss your liquid chiller sound compressor noise problem: 888.213.4711.