Sources of Noise Outside Data Centers

Data centers are critical infrastructures housing vast arrays of servers, storage systems, and networking equipment. These facilities are essential for handling the enormous volume of data generated by modern digital activities.

Data centers require continuous power for uninterrupted service. Multiple redundancies in providing back-up power must be planned for in case of a power outage. Also, the server rooms need to be kept cool to operate efficiently.

Noise from Diesel Engine Generator Set and Air Cooled Chillers

Diesel Engine Generator Set, or Genset as they are commonly called, are used primarily for emergency power generation or stand-by power in case of power failure. In the case of emergency power, the gensets are an extremely important piece of equipment for Data Centers. Stand-by gensets provide back-up power that can be relied on to power their day-to-day operations.

As you may have noticed, many of these facilities are familiar and located in your neighborhood or near noise sensitive areas. Here lies the importance of genset noise control and acoustical enclosures.

Diesel Engine Generator Set Noise Control

Diesel power generators provide insurance and peace of mind in an emergency, but all other times we do not want to know they are there. Gensets will typically need to be tested on a regular schedule to insure operation in case of an emergency. Due to the testing schedules of the generators, noise control is an issue that needs to be addressed adequately so as not to disrupt normal business routines to test an emergency or back-up system.

Gensets have three areas that create most of the the high sound levels. The motor, the motor exhaust, and the radiator or cooling fan. The motor and radiator require large volumes of air to keep them cool and operating. In sound enclosure design, adequate ventilation is critical. In essence, you are going to place a large enclosed box over the genset, then cut big holes for airflow, and expect it to reduce the noise.

Typically the acoustic enclosure is constructed of heavy gauge solid steel outer skin, a perforated steel inner skin, and sound absorbing insulation filling the void between the two. The steel outer skin functions as a noise barrier (mass blocks noise!) and the absorber layer reduces reverberation within the enclosure. These steel assemblies are constructed of large sheets or modular panels.

To tackle the motor cooling airflow requirement, acoustical silencers are utilized. The sound attenuators are typically constructed of the same materials described above, utilizing solid steel, perforated steel, and a sound absorptive material. The silencers are designed for minimum pressure loss and maximum sound reduction. This entire assembly of acoustical sound barrier panels and sound attenuators provide noise control as well as adequate airflow to improve data center acoustics.

Air-Cooled Chiller Noise Control

The chillers supply cold water and cool air to the Data Centers they service. The chillers operate by drawing air via large fans over copper coils filled with refrigerant that is transported by compressors. Air-cooled chillers generate noise, and if located in a sound sensitive location, will need to be treated with noise control soundproofing.

The main noise source is the compressors. The compressors emit a whine at a frequency that is particularly bothersome to the human ear. The second noise source is the condenser fans. The fans generate a low frequency drone that will carry for some distance. Other sources of noise are the compressor piping, oil separators, and the sheet metal housing.

eNoise Control can help you reach your chiller noise reduction goals with the many sound control products that can be applied to your chiller application. We recommend assessing your chiller noise control project and estimating the level of sound reduction you will need to reach your goal. Most chiller manufacturers can provide sound power data on their units, and we can use this acoustical data to predict what the sound level will be at certain distances from the chiller. If the client needs to meet a local noise ordinance or code, we can assist in designing a sound control system to meet the project’s objectives. We employ CadnA environmental predictive software to assist our clients in assessing the current sound levels and what different levels of noise control solutions will provide to obtain their acoustical goals.

Sound Reduction Solutions

The solution options are outlined in the following table, with each solution explained in more detail on the construction, installation, and performance.

| Sound Reduction Product | Decibel Reduction | Highlights | Description |

| Economy Sound Blanket | 3 – 4 dBA | Minimum Treatment | Removable acoustic blankets for compressors only. Stainless steel wire / 2.5” Velcro vinyl flaps Double sewn construction |

| Enhanced Sound Blanket | 4 – 8 dBA | Better Sound Reduction | Removable acoustic blankets for compressors, piping, and oil separators. Higher sound reduction |

| Fan Silencers | 6 – 20 dBA | Fan Noise Above Unit | Acoustical Silencers designed for the units airflow and pressure loss requirements. Primarily noise above the unit. |

| Sound Curtain Barrier | 10 – 12 dBA | Blocks Line of Sight | Exterior grade curtains straight wall or multiple sides covered. Easily attaches to chain link fence. |

| Steel Sound Barrier | 10 – 14 dBA | Lower Frequency | Modular Steel Sound Barrier Wall with absorptive panels supported by structural steel columns |

| Full Sound Enclosure | 15 – 30 dBA | Highest Noise Reduction | Full Sound Enclosure with absorptive panels and intake and exhaust silencers designed for units airflow and pressure loss. |

Economy Sound Blankets

This noise control option is an easy to install and remove compressor sound blanket that provides sound reduction of the compressors only. It is an easy add-on to the specifications of supply, and typically reduces the noise levels by 3-4 dBA, which takes the edge off the annoying tonal whine of the compressors. The sound blankets are constructed from materials suitable for being outdoor for 10+ years and a good choice for many HVAC chiller applications.

Enhanced Sound Blankets

This noise reduction option builds on the compressor sound blanket by adding coverage of additional noise generating items on the chiller – compressor intake and discharge piping, oil separator and/or economizer. This added coverage from outdoor sound blankets can provide sound reduction up to 4-8 dBA overall and is rated for many years of outdoor service.

Fan Silencers

Chiller or condensing fan silencers are a good option for unit noise control if the subjects to receive the noise are located above the unit. Multi-story office buildings and apartments with units located on adjacent roof or on-grade can be affected by the fan discharge noise as well as the compressor sound exiting the top of the unit.

The fan silencers are engineered with very low-pressure loss and designed to accommodate the published CFM of the subject fans, providing high sound reduction performance to areas above the unit. These fan silencers are constructed of galvanized solid and perforated steel and acoustical grade fiberglass, and are typically supported with a structural steel frame because their weight can exceed what the unit’s casing is designed to support.

Sound Curtain Barrier

Outdoor sound curtain barriers provide an easy to install and low-cost solution as a sound barrier wall. The sound blankets can be attached to new or existing chain link or stockage fencing. The sound curtains offer an acoustical absorber and sound barrier in a rugged outdoor rated engineered material. This is a very popular solution for schools and businesses with an existing chiller security fence. The blankets can be attached with nylon wire ties, tie wire or mechanical fastener through the provided grommets located across the top and bottom of each blanket.

Full Sound Enclosure

This solution offers the highest level of noise reduction. A full sound enclosure with four sides and a roof around the chiller with silenced intake and exhaust silencers to allow the required airflow for the operation of the unit. Constructed of a structural steel frame and modular steel panels constructed of 16 gage solid outer skin and 22 gage perforated inner skin filled with acoustical grade sound absorber. This enclosure contains all the chiller compressor and fan noise while acoustical silencers allow for the quiet exchange of large volumes of air to allow the chiller to function at its optimum levels.

Steel Sound Barrier

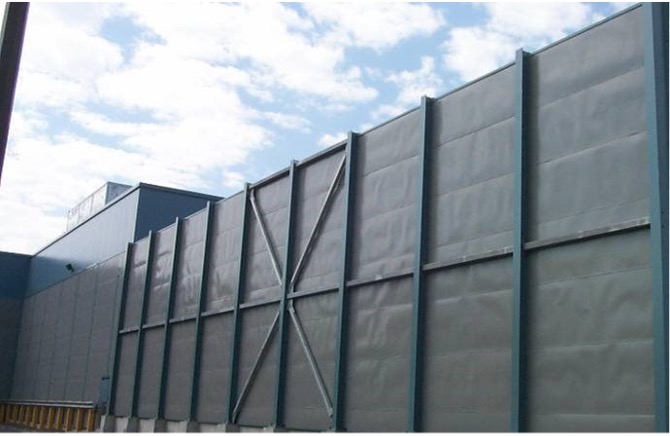

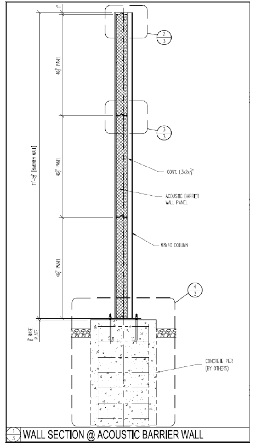

Modular steel panel sound barrier walls are becoming commonly used at data centers as a solution for noise control, addressing both regulatory requirements and community noise concerns. These barriers are designed to mitigate the substantial noise generated by cooling equipment, backup generators, and air handling units that are vital to data center operations. As the global demand for data storage and processing continues to grow, the expansion of data center facilities into neighborhoods and downtown environments has made noise management a critical consideration.

The steel sound barrier walls are constructed of I-beam structural steel columns with baseplates designed and sized for the local wind load and modular steel panels constructed of 16 gage solid outer skin and 22 gage perforated inner skin filled with acoustical grade sound absorber. This construction offers longevity and durability as well as superior noise control of your chiller unit.

The use of modular steel panels offers several advantages in the context of data center noise control. First, steel panels provide a high level of acoustic insulation due to their density and rigidity. Typically, these panels incorporate internal layers of sound-absorptive materials, such as mineral wool, sandwiched between perforated steel skins. This composite structure not only reflects and absorbs sound but also resists weathering and mechanical damage, making it suitable for outdoor installation around noisy equipment.

The use of modular steel panels offers several advantages in the context of data center noise control. First, steel panels provide a high level of acoustic insulation due to their density and rigidity. Typically, these panels incorporate internal layers of sound-absorptive materials, such as mineral wool, sandwiched between perforated steel skins. This composite structure not only reflects and absorbs sound but also resists weathering and mechanical damage, making it suitable for outdoor installation around noisy equipment.

Modularity is a key attribute of these systems. Prefabricated steel panels can be quickly assembled and customized on-site to meet the specific acoustic and size requirements of the data center. This flexibility is very useful for facilities with complex layouts or evolving operational needs. Modular systems also allow for easier maintenance and changes in the future, which is needed as data centers upgrade or expand.

Beyond their functionality, modular steel sound barriers contribute to regulatory compliance. In many jurisdictions, noise ordinances mandate that facility-generated sound does not exceed specific decibel levels at property boundaries. By reducing equipment noise, modular barriers help ensure that data centers remain within acceptable noise limits, avoiding potential fines and neighborhood complaints. This is especially important in mixed-use areas where residents may live near industrial facilities.

Beyond their functionality, modular steel sound barriers contribute to regulatory compliance. In many jurisdictions, noise ordinances mandate that facility-generated sound does not exceed specific decibel levels at property boundaries. By reducing equipment noise, modular barriers help ensure that data centers remain within acceptable noise limits, avoiding potential fines and neighborhood complaints. This is especially important in mixed-use areas where residents may live near industrial facilities.

Aesthetically, steel panel systems can be engineered with finishes and textures that blend with their surroundings or enhance the visual appeal of an industrial site.

Ease of installation is another advantage. Compared to traditional masonry or poured concrete walls, modular steel panels require less time and labor to install. This is beneficial for new data center projects as well as retrofits where noise control equipment must be added without disrupting ongoing operations. The reduced installation time can translate to lower costs and quicker compliance.

Sources of Noise Inside Data Centers

The primary sources of noise inside data centers are the servers and the cooling systems. Servers produce significant noise due to the high-speed fans used to keep the equipment cool. Additionally, HVAC (Heating, Ventilation, and Air Conditioning) systems contribute to the noise level, as they are essential for maintaining optimal operating temperatures. Other sources include power distribution units (PDUs), uninterruptible power supplies (UPS), and network equipment.

Because data centers are large open buildings with hard surfaces on the wall floors and ceilings, there is a lot of reflected noise generated by the noisy fans and equipment. Adding acoustical absorption to the space will help reduce the reflected noise and make the acoustics in the room better by lowering the overall noise level of the space. Typical examples of acoustical absorption products are acoustical ceiling baffles, acoustical banners and acoustical wall panels. Using Sabin’s reverberation time calculator, we can calculate the amount of acoustical absorption to add to get the optimum sound reduction. Typically the addition of the correct amount of sound absorption can reduce overall sound in the space by 3-6 dBA.

Most times there are areas with a concentrated amount of noise coming from equipment. These are typically the noisiest areas in the data center. These areas can be sound isolated with acoustic enclosures. Sound curtains – a barrier/absorber composite material can be easily installed to surround the nosiest areas to make the space a better work environment for employees. Sound curtains can be an effective, and economical solution to data center interior noise. Typically, an open-to-sound curtain wall can reduce noise by 10-14 dBA.

Contact our team about your data center noise issues at 888.213.4711 or send us an email to info@enoisecontrol.com.