Quiet Room: In-line Sound Test Case Study

Situation:

A manufacturer of electric motors contacted eNoise Control requesting that we perform a simple sound test on each motor at a station along their production line in which the operator listens to the motor as it runs to detect if the motor is running correctly.

Their problem was the ambient noise in the manufacturing facility was too loud to effectively perform this test. At present, they were transporting the motors to another area to do the testing, thus disrupting the smooth flow of production.

eNoise Control conducted a sound level reading around the area where the testing was being performed and worked with the customer on establishing a goal for the sound levels needed for the testing. The facility’s ambient sound levels were 78 – 83 dBA and the goal for the testing was 55 – 60 dBA.

The customer required a solution that would allow the motors to travel through by conveyor, enclose the testing station and its operator, and provide access for maintenance of the test equipment.

Solution:

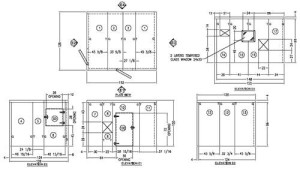

Quiet Room Diagram

eNoise Control’s solution was a modular steel acoustical enclosure.

We designed and supplied an enclosure with:

- cutouts for the conveyors

- personnel and equipment access doors

- windows to view incoming motors

- air conditioning

- silenced ventilation

The “Quiet Room” exceeded the customer’s sound level goals and they are planning to add similar in-line test rooms to the other assembly lines.