Clean Room Sound Panels for Bowl Feeder

Situation

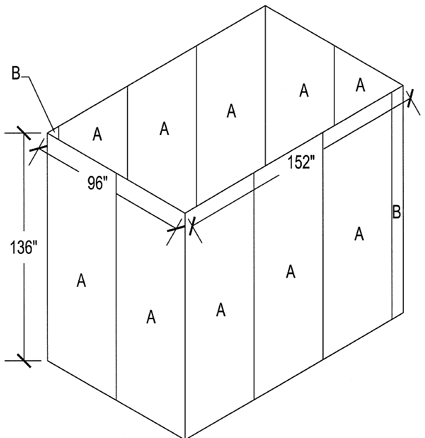

A pharmaceutical company purchased a new vibratory bowl feeder for the production line. The company was installing a suspended frame over the new feeder and was interested in mounting sound panels to the frame. Because the production line was a clean room, they had specific requirements for the materials. The panels had to be fiber free, no overlapping or hidden areas for mold growth, no Velcro, and surfaces that could frequently be wiped down for cleaning. Additionally, the panels needed to block noise from leaving the framework and limit the exposure to the surrounding workers.

A pharmaceutical company purchased a new vibratory bowl feeder for the production line. The company was installing a suspended frame over the new feeder and was interested in mounting sound panels to the frame. Because the production line was a clean room, they had specific requirements for the materials. The panels had to be fiber free, no overlapping or hidden areas for mold growth, no Velcro, and surfaces that could frequently be wiped down for cleaning. Additionally, the panels needed to block noise from leaving the framework and limit the exposure to the surrounding workers.

Clean rooms provide an extra challenge to noise control problems because the products are required to meet certain standards set by the Food and Drug Administration. This means that many common absorptive materials cannot be used. eNoise Control offers several clean room noise control products that adhere to these rules.

Solution

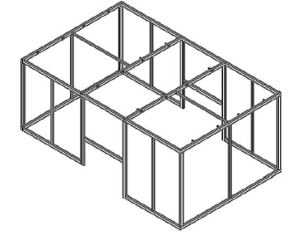

eNoise Control recommended clear vinyl sound barrier panels for their clean room application.

eNoise Control recommended clear vinyl sound barrier panels for their clean room application.

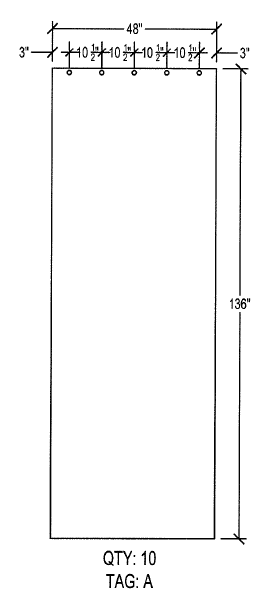

The panels feature grommets across the top for easy suspension. They easily mounted to the frame with fasteners and the flexible barriers provided both visual and physical access to the bowls for adjustment. The Model UN-10CV panels are approximately 3/16″ thick and weight 1 lb per square foot. The sound blocking performance for the clear vinyl panels is STC 27.

We also recommended adding several FDA sealed acoustical baffles. These baffles hung from the top frame structure for sound absorption and lowered the noise within the enclosure.

eNoise Control can provide a solution for your clean room noise problem. Call us today to discuss your application and learn about the options available to mitigate the noise.